Rafer: Glossary

Custom Material Handling Chains

Adjustment:

Assembly of an outer piece (bore) and an inner piece (shaft). The male (shaft) and female (bore) parts have the same nominal dimension but different tolerances, providing either positive clearance, interference fit, or uncertain clearance. Bore: Operation that consists of carefully machining the inner surface of a cylinder or any other hollow piece. It is also the result of this operation.Shaft:

Mechanical component transmitting power in the form of torque and rotational movement. The cylindrical shape of this component is the origin of its name.Axle:

Straight mechanical piece around which one or more other parts rotate; it serves solely to guide in rotation or translation. The choice of diameter for an axle is crucial. For proper guidance, the length should be at least twice as long as the diameter. The axles of these chains are usually solid, but they can be hollow for attaching accessories or spacers connecting two parallel chains.Burr:

Describes an unintentional excess of material, often of very small thickness, as if the material had burrowed. It is unsightly and can be sharp.Bloom:

Steel bar with a square or rectangular section larger than a 120 mm square (160 mm at some steelmakers), of variable length intended to be engaged in rolling mills called finishing mills.Bolt:

Assembly component consisting of a screw with uniform threading and a flat end (or threaded rod), and a nut (and possibly a washer).Carburizing:

Thermochemical treatment that involves superficially introducing carbon into steel, where the percentage of carbon is insufficient for quenching, in order to transform the surface into highly carburized steel capable of being quenched.Breaking Load:

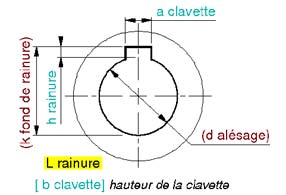

Weight of the load that causes the chain to break (permanent deformation or destruction)Key:

Metal pin forcefully inserted into a notch made in a part to press it against another, or between two parts to make them solid and prevent rotation.Coefficient of Safety:

To determine the breaking load of a chain, it is necessary to apply a safety coefficient to the force F. Breaking load = F x safety coefficient This coefficient depends on the operating conditions. It can vary between 5 and 12, but generally falls between 7 and 10. However, it's important to verify the joint pressure before making the final chain selection, as this can be a determining factor.Traction Coefficient (CT):

A variable parameter depending on the state of the rolling path, lubrication, and the diameter of the chain's roller, as follows: - 0.10 for a standard roller chain, well lubricated and clean rolling path - 0.15 for a standard roller chain, uncertain lubrication and cluttered rolling path - 0.20 for a small roller chain with uncertain lubrication and cluttered rolling path - 0.33 for direct friction of plates on steel path - 0.02 to 0.05 for ball-bearing rollers (the larger the roller diameter, the smaller the coefficient)Conveyor:

A device for continuous handling in a closed loop, used for airborne or ground transportation of loads or materials.De-gritter:

A handling device used to remove debris that accumulates on grids.Tooth Profile:

The set of teeth on a toothed wheel, usually cut but can also be oxy-cut and ground for special profiles or very large rollers.Pitch Diameter:

The distance between the center of the wheel and the approximate center of the teeth. DP = pitch/sin(180°/number of teeth)Ductility:

Refers to the ability of a material to deform plastically without breaking. Rupture occurs when a defect (crack or cavity) becomes critical and propagates.Bushing:

Cylindrical metal endpiece used to assemble two parts while protecting the axis.Hardness:

For metals, it defines the resistance that the surface of the sample opposes to the penetration of a harder body, such as a ball or the point of a durometer.Lock:

A structure located between two bodies of water with different water levels, enabling vessels to move from one level to another using movable elements like gates and valves.Elevator:

Device or machine used to transport loads or materials vertically or on steep inclines.Enameling:

Depositing a glassy, transparent, or colored layer onto metal or another support. The object to be enameled is covered with pigments suspended in a volatile oil and then exposed to a temperature of around 800°C: the oil evaporates, and the melted pigments bond to the support. Enamelled objects are highly durable, resistant to scratches and chemical agents, and easy to clean.Spacer:

A tube-shaped piece intended to maintain a constant gap between 2 ball bearings.Asphalt Mix:

A mixture of aggregates and filler coated with bitumen or tar, used for the upper layers of roads and for watertight coatings in canals or dams.Shoulder:

A sudden change in diameter, typically intended to serve as a bearing surface for another part.Oven:

A location where the temperature is very high and humid.Excavator:

An earthmoving machine equipped with a bucket chain mounted on a boom or a digging wheel.Thread:

Consists of one or more helical grooves on a cylindrical outer surface.Roller:

A roller with a diameter greater than the height of the plates. They enable the chain to roll on a flat surface. Rollers can be straight or shouldered to provide lateral guidance. Straight or shouldered rollers are made from treated steel.Bucket:

A type of container with varying capacity and shape used in various handling devices (dredges, elevators, excavators, etc.) for digging the ground.Pivot Pin:

A small metal piece inserted into the end of certain elements to create a removable rigid assembly. It immobilizes or positions a piece relative to another, acts as an axis, and serves as a safety component (shearing in case of overload).Greaser:

A device within a machine that automatically supplies grease or lubricant to moving parts.Shot Blaster:

A machine that projects shot in the form of microbeads to remove surface material from an object.Seizure:

Mechanical failure between two metal surfaces rubbing against each other, where metal particles detach from one surface and scratch the other more or less deeply, causing heating and subsequent welding of the surfaces in contact.Log:

The trunk of a felled tree, trimmed, and stripped of its branches and canopy.Guidance / Alignment:

The quality of chain guidance during its movement and the alignment of the driving sprockets are crucial. These aspects should be systematically checked before starting new equipment.Clearance:

The space left between two imperfectly assembled parts. Since it's impossible to create parts with perfect geometry, clearance is a necessity in assembling the components of a mechanism.Joint:

A device enabling the transmission of rotational motion between two shafts whose relative position is poorly defined, incorrect, or variable.Rolling Mill:

An industrial installation aimed at reducing the thickness of a material (usually metal). It also allows the production of profiled bars (long products).Yield Strength:

The stress at which a material begins to deform irreversibly.Lubrication:

It is recommended to grease the return strand of the chain. This facilitates access to the lubricant in the core of the chain joint. The quality of the lubricant used and the care taken in its application to the chain can significantly affect its behavior and lifespan.Link:

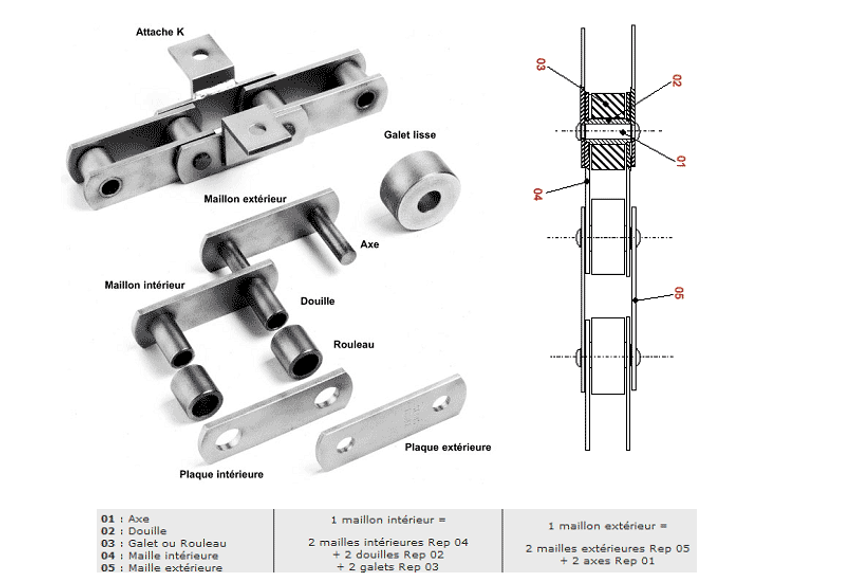

Metal plates connecting the articulation pieces. There are inner links in direct contact with the bushings and outer links in direct contact with the pin. Two inner links, as well as two outer links, form a link.Self-Locking Nut Joint Links:

The two axes are riveted to a plate at one of their ends, the other end receiving a joint plate immobilized by self-locking nuts.

Pin-Jointed Links:

Where the joint plate is immobilized by pins to facilitate disassembly. For certain applications, we can deliver chains with pin-jointed outer links on one side.

Flat:

A flat surface on a cylindrical piece.Hub:

A central piece on which parts that need to rotate around an axis are assembled. It can be offset or symmetrical (hubless wheel = disc).Nitriding:

A thermochemical treatment leading to the formation of nitride(s), aimed at surface hardening of the treated parts.Pitch:

Refers to the distance between the centers of consecutive primitive axes. The pitch should be chosen according to the conditions of use, the type of product to be transported, the frequency of accessories, the available space, etc. Not all pitch values established in a standard series are achievable: refer to the table in Chapter 2 for preferred pitches. Intermediate pitch values or pitches in inches can be realized.Shutdown / Storage Periods:

Some applications may have long shutdown periods. It is absolutely necessary to take all possible precautions to protect the chain from corrosion by applying suitable lubricant.Plates with Attachments:

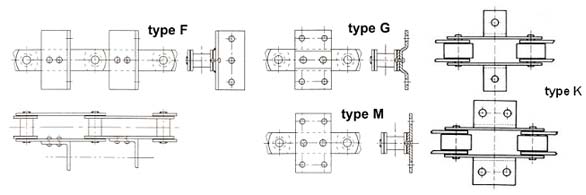

These can be achieved through folding or as brackets attached by welding or riveting: - "M" attachments with one or more holes forming a fastening plane parallel to the plates. - "K" attachments with one or more holes forming a fastening plane perpendicular to the plates, with a choice of three hole spacing values (K2 with short, medium, and long spacing). The width of the attachments varies accordingly. These attachments can be applied to inner or outer links, on one or both sides, according to a frequency and arrangement specified upon ordering. - Special attachments can be created upon request for sufficient quantities.

Polishing:

Making smooth and, optionally, shiny.Offset Plates:

Asymmetrical plates designed for directly placing loads on the chain, rolling on straight rollers. These chains are generally used in parallel to form a conveyor and distribute the loads.Perforated Plates:

With one, two, or three holes to accommodate attachments or spacer bars. If these bars pass through the chain, it is necessary to make clearances in the wheel teeth.Weight of the Apron:

Total weight of the considered section, including the entire moving part: chain + rollers + pallets + accessories, etc.Articulation Pressure:

In some applications, contact pressure at the joints becomes a determining parameter. This pressure, during each chain oscillation while passing over the wheel, causes chain wear. This pressure should be monitored, especially in abrasive environments, without maintenance, in stainless steel chains, etc.P = F/S

P in N/cm²

F = tangential force in the chain in N

S = projected diametral surface, i.e., Ø of the pin (in cm) x bushing length (in cm)

Pressure values for standard chains can be:

4000 N/cm² with abundant lubrication

3000 N/cm² with proper maintenance and clean environment

1500 N/cm² with uncertain maintenance and dusty environment

1000 N/cm² without maintenance

Groove:

Long notch, rectangular in section, T-shaped, or dovetail, made in a piece.

Efficiency:

A coefficient that takes into account the efficiency of the components situated between the motor and the drive shaft: coupling, reducer, chain transmission, etc. Of course, these coefficients accumulate. Furthermore, a coefficient of 1.05 is applied to each 180° wrap. This coefficient corresponds to losses due to chain joint movements, their placement on the wheels, and the rotation of the wheel and shaft assembly.Minimum Tensile Strength:

Ranges from 20 to 900 kN according to a series based on standard numbers.Rivet:

A permanent assembly element. It is in the form of a cylindrical rod, typically metallic, solid or hollow, with one end having a head, i.e., a larger cross-sectional part. The other end is flattened and widened through compression to join the elements that need riveting.Washer:

A small pierced disk placed between a screw or nut and the piece to be tightened to transmit and distribute the clamping force on the piece.Gear Wheel:

A circular component with teeth around its periphery used to transmit motion. Gears transform rotational motion into translation. The gear wheels used with handling chains are typically made of welded steel or cast iron. The teeth are normally raw from casting or oxy-cutting, but upon request, they can be delivered with cut teeth, which is imperative when using bushing chains. The hubs are offset from the tooth profile plane unless specific instructions specify a symmetrical hub. The gear wheels can be provided bored and grooved. In the case of a key with a slope on an offset hub, the entry of the key is designed on the tooth side unless otherwise indicated.Roller:

A small cylindrical revolution piece made of very hard steel, carburized, hardened, or subjected to other treatments and perfectly polished. Used in mechanical construction, they protect the bushings and prevent tooth wear.Ball Bearing:

A bearing's purpose is to reduce friction between two rotating parts, thereby reducing the heat generated by rotation. Bearings can also be used to mitigate alignment issues between two pieces. It's important to note that there are several types of bearings: ball bearings, roller bearings, needle bearings.